Integrity Print Ltd, the £60m turnover print group, that includes A1 Security Print, has moved into the manufacture of medical specimen bags. The specialised nature of the products has involved acquiring two finishing lines from the assets of the recently closed Tressanda print business. Tony Pelgrave, formerly Sales Manager at Tressanda, has joined Integrity to help develop and grow sales of the product, along with two key members of the production team.

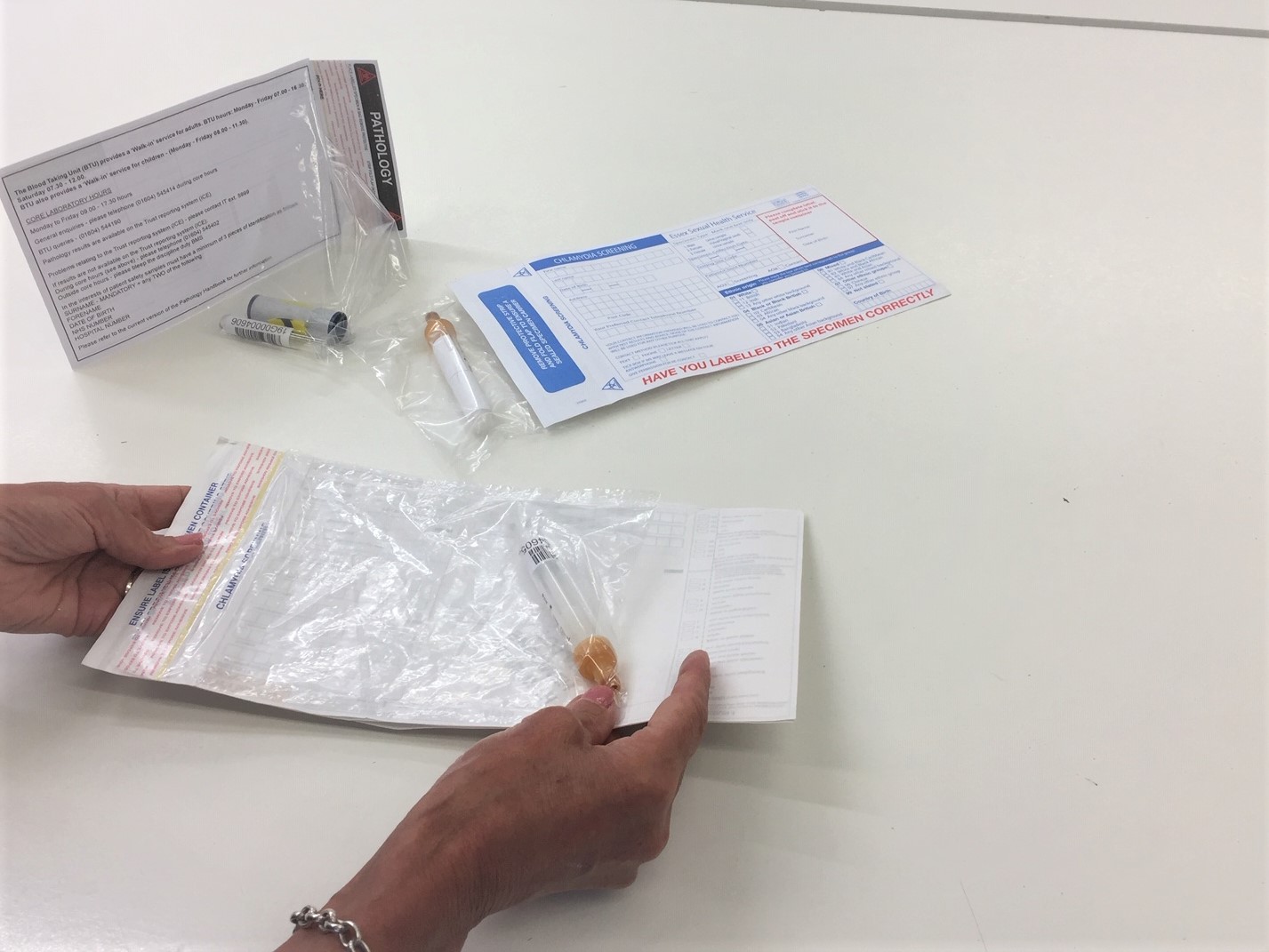

Specimen bags are widely used in the NHS to securely transfer fluid samples between departments and laboratories and feature a leak proof adhesive seal. The Specimen bags can be combined with a pre-printed paper form to create multi- part carriers with integrated labels. Integrity also have the facility to add variable barcodes and unique numbering to the product to ensure accurate distribution and reconciliation of samples.

The specimen bag department will be run as part of the Security Print Division headed up by Jim Richardson of A1 Security Print limited.

Commenting on the decision to produce the Specimen Bags, Sales and Marketing Director Andrew Law said “We are providing increasing amounts of print to NHS Trusts and Tressanda’s customer base was closely aligned with many of our existing trade clients. This gives our clients the opportunity to source a wide range of products more effectively through a single supplier. Our business strategy is to diversify our print offering, enabling us to add more value to our clients, and the ability to produce specimen bags meets this objective.”

Recent Comments